Test rigs for wind turbine blades

From concept to hardware - design and calculation

With more than 23 years of experience delivering to the wind industry, it is our estimate that we can deliver test rig designs for blades of approx.: +50 tons, +140 meters length and root diameters of +6 meters, with bending moment of +150 MNm.

Our experience designing for the wind industry involves designs of onshore and offshore wind turbines, and components such as test rigs, lifting equipment and transportation equipment.

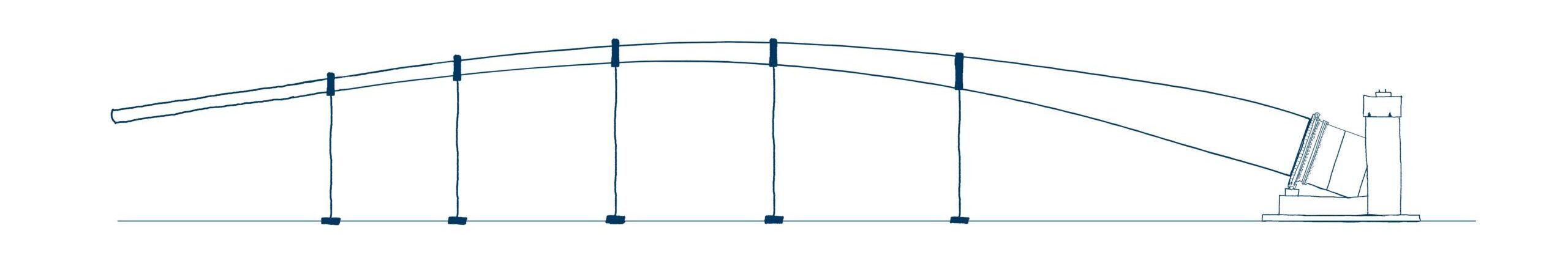

Visualization of innovative test rig using a tilting function

Considerations when designing a test rig

Designing a test rig for wind turbine blades requires thorough and specialist knowledge. Both a CAD and FEM team need to be involved to reach the optimal design, functionality, and lifespan of a test rig.

Consideration must be made as shown in the questions below:

- How heavy and how long are the blades going to be?

- What are the extreme and fatigue loads for flapwise and edgewise test?

- What other load cases are there to take into consideration?

- What are the functional requirements? E.g., pitching and tilting of blade.?

- Should the test rig be designed for one sized blade roots or applicable for various sized blade roots?

functions should it have, and which fatigue loads are critical to build the design around? From there we begin the process of developing a concept that can fulfill the requirements. Itis crucial to involve people with the right skills and experience.

What is your neeed?

A test rig that tilts, pitches, adapts to different blade root sizes, or stays the same?

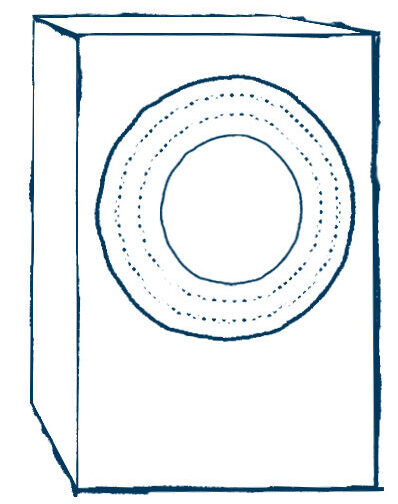

Visualization of advanced modularized adaptor allowing to mount different sized blade root diameters

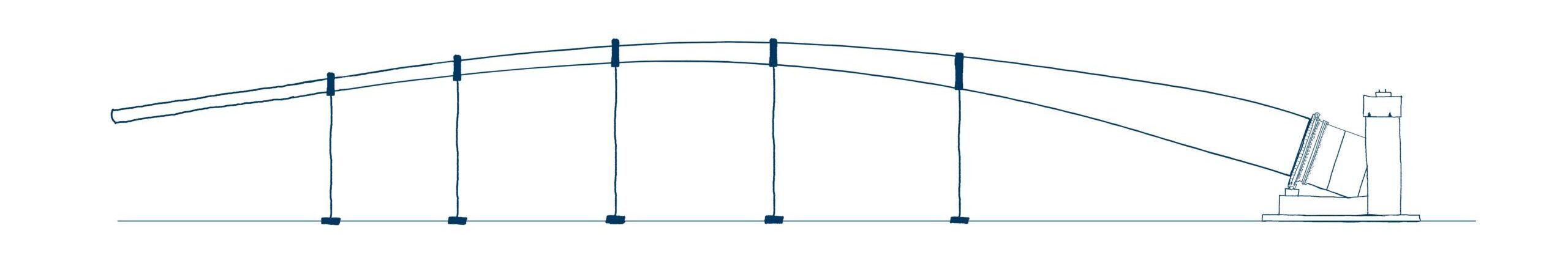

Visualization of innovative test rig using a pitching function

Visualization of innovative test rig using a tilting function

Functionality

Test rigs can be designed in various ways depending on customers’ needs. Some require the functionality of a tailored test rig suitable for just one size blade roots while others require test rigs that adapts to various sized blade roots. Another functionality consideration is whether the test rig should be a solid block or a dynamic design with moveable parts.

In the illustrations above a test rig is designed with three functions in mind: A static function, a tilting function, and a

pitching function.

These three functions, in particular, make the test rig capable of performing two main tests without remounting the blades: accelerated fatigue tests and static tests. At FRECON our highly professional teams are ready to support your development offering solid knowledge in mechanical engineering including concept development, calculation, and design.

Test rig in use for static test

Test rig for one sized roots

Loads

Fatigue loads is an extremely important skill to master when designing a test rig

and designing its assemblies. Components such as bolts, welds and bearings are

examples of critical assemblies. It is one of the biggest challenges when designing

the mechanical construction, a test rig is.

explains Sebastian Mikkelsen.

Bolts, welds and bearings not only makes the test rig stable and functioning,

it also takes part in ensuring that the forces inflicted on the test rig during

tests are transferred to the concrete piles in the foundation.

Our expertise

At FRECON we have 23 years of experience in designing for the wind industry. We have designed onshore and offshore wind turbines, and components such as test rigs, lifting equipment and transportation equipment. We calculate and design accordingly to requirement specification and at the same time challenge assumptions to reach the optimal design. Throughout a collaboration we share our expertise hence, offering you the best conditions for successful design.

If you wish to hear more contact our Key Account Manager Zita Louise Videler.