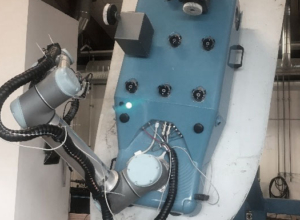

Further development of mobile blaster and preparation for CE certification

FRECON has been responsible for the further development of the customer’s prototype so it complies with current standards for CE certification. The work involved calculations, changes to the construction and preparation of documentation.

The customer in question develops, manufactures and sells a wide range of equipment for surface treatment, including solutions for the entire process prior to, during and after the surface treatment (e.g. ventilation). The products are sold all over the world.

New standards presented new challenges

“We had been sitting for some time on a prototype for a mobile blaster which we wanted to have updated and prepared for potential CE certification and production,” says the customer’s CEO. We contacted FRECON, as we did not have the necessary resources to do the job ourselves.

Review and documentation

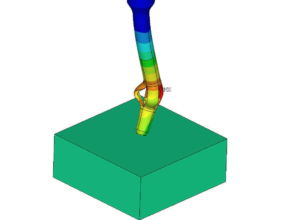

After an initial introduction to the job by the customer, FRECON took over responsibility for the job. Initially FRECON made extensive calculations of the current blaster in accordance with applicable rules for pressure equipment and prepared a full set of documentation. Both are requirements for approval by a third party such as Bureau Veritas.

With the customer’s help, all documentation from current sub-suppliers was also made available, as it had to be included in the future set of documentation.

Good dialogue with suppliers and authorities

Throughout the process, FRECON enjoyed a good dialogue with potential new sub-suppliers in the market, which FRECON had identified – suppliers who can live up to the new standards in connection with the future production of the blaster. FRECON also had extensive discussions with the authorities about the forthcoming approval and made sure that everything is in place for the CE certification of the blaster.