Robot for cleaning and maintaining wind turbine blades

FRECON joins an exciting product-development journey

The Aarhus-based company Rope Robotics has developed an automated BR-8 robot that can crawl out onto the enormous blades of onshore and offshore wind turbines and make repairs and do maintenance tasks that previously could only be done manually. The wind turbine owner or manufacturer can use the robot to dramatically increase safety by eliminating the need to have employees climbing around in a risky, complex environment. At the same time, the robot is very efficient and significantly reduces costs. FRECON A/S is proud to have been involved in developing the robot.

According to Hans Laurberg, CEO, Rope Robotics, billions are spent on repairing and maintaining wind turbine blades. The blades are worn down by wind and weather – particularly rain and sand. At worst, offshore wind turbines can develop wear problems as soon as 2.5 to 3 months after commissioning, and this can quickly become a costly affair for the wind turbine manufacturer, customer or insurance company.

Robot that uses AI

This concern was dealt with by two engineers, Martin Huus Bjerge and Hans Laurberg, who met while working at Siemens Gamesa Renewable Energy. Together, they came up with the idea of manufacturing a robot with AI that could automate the repair and maintenance of wind turbine blades. Rope Robotics started in May 2016 with funding from the Energy Technology Development and Demonstration Program (EUDP) and Horizon 2020 (EU’s research and innovation programme for years 2014–2020).

CEO, Rope Robotics

Robot with huge diversity

The robot is extremely complex, since there are many processes that must be automated, such as filling, grinding and painting. In addition, the surface of a wind turbine blade’s leading edge is relatively small, the environment is chaotic, and the blade’s shape varies from model to model and from manufacturer to manufacturer. Damage can make the task even more complicated. All this means that the robot must be very versatile.

The robot does not have a joystick but only reacts to pre-programmed commands. And one of the huge challenges at the outset was whether the robot would fall off because no machine had ever crawled out onto the blades before. Fortunately, it didn’t.

The only manual work involved is ‘pressing the start button’, getting the robot onto the blade and then carrying out quality control of the scanned images transmitted by the robot.

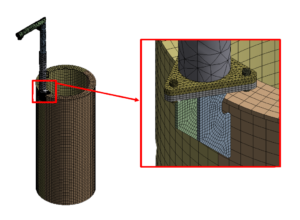

In addition, we designed different mechanical components, and we made the production foundation, strength calculations and flow calculations using Computational Fluid Dynamics (CFD).

Rope Robotics has its pulley patented, by the way.

Picture: Hans Laurberg with the pulley designed by FRECON and patented by Rope Robotics.

At FRECON, we believe that Rope Robotics has created something with great potential, and we are extremely proud to have been part of the development process.