New catheters for user-friendly infusion kits for patients with diabetes

Close collaboration on development and design with Unomedical (Convatec)

Many diabetics must use a small pump every day to inject insulin (popularly known as a drop). Connecting the drop is not always easy and there is a risk that the patient incorrectly inserts it, hitting muscle tissue instead of fatty tissue.

Incorrect insertion ruins the device’s functionality

If a patient incorrectly injects needle into muscle tissue instead of fatty tissue as instructed, this can cause the thin, small catheter (0.7 mm diameter) that is supposed to inject the insulin to become blocked.

New user-friendly infusion kit

This is why Unomedical has developed an infusion kit where the infusion device and kit are assembled in one sterile unit. Unomedical wanted a catheter specially designed for the kit that could make allowances for the patient making an incorrect injection.

Design & Development Engineer, Unomedical

Task: Comprehensive calculations

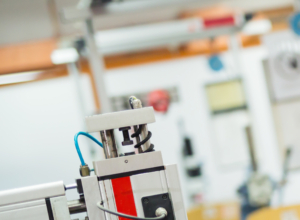

In collaboration with Unomedical, FRECON was responsible for carrying out the task, which was to challenge the traditional design of a catheter with a hole in the end.

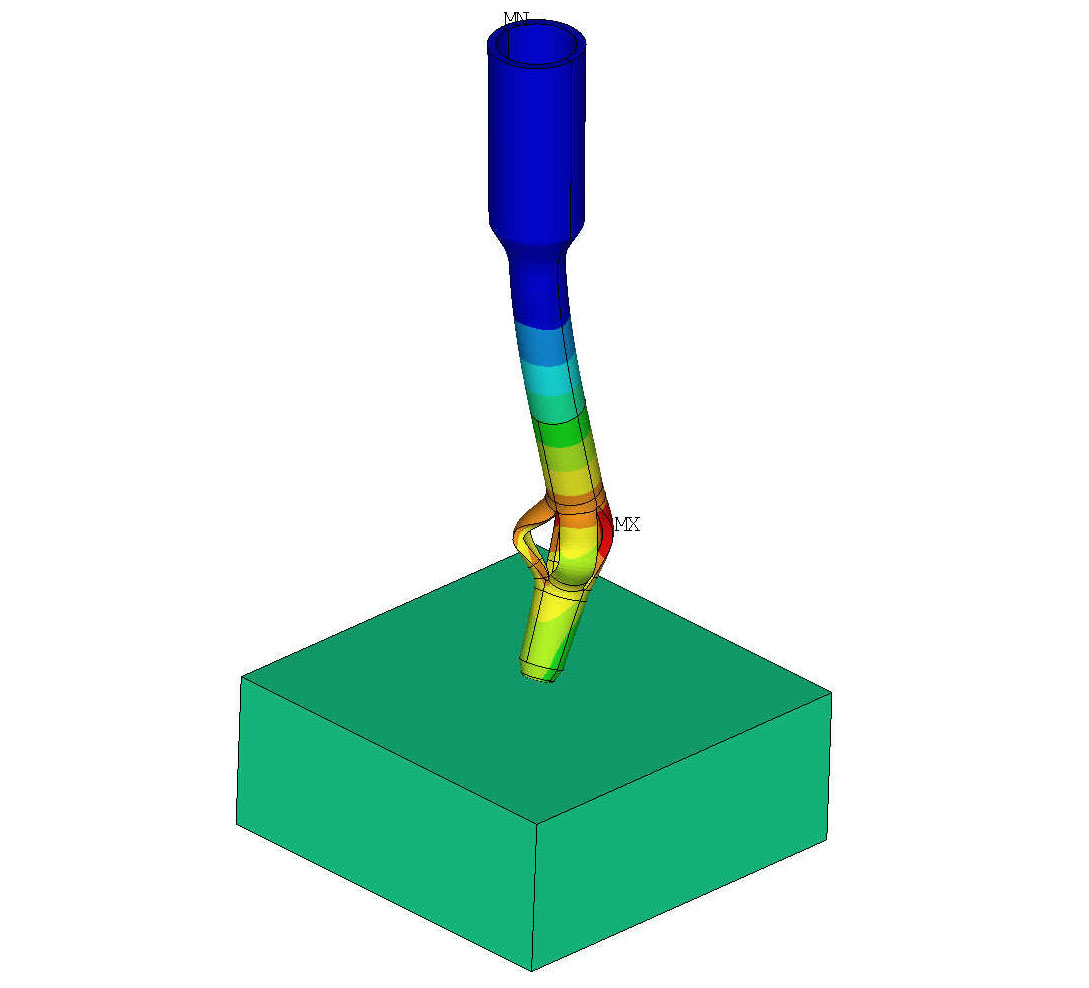

“Unomedical wanted to insert slits in the catheter, which is made of soft plastic. Therefore, we calculated different configurations of these slits and found the one that gave the best opening of the catheter. We’re talking about something as small as just 0.7 mm in diameter,” explains Rasmus Lundby Høyer, Design Specialist (FEM/FEA), FRECON.

New marketing possibilities

With the newly designed solution, the customer now has a product that provides them with completely new marketing possibilities.

Watch the video at the bottom of this page.

As part of the comprehensive calculations to find the ideal position of the small slits in the catheter and their size, we developed a transient calculation model in ANSYS, made from a small block, which would simulate a “muscle” and which could be moved up and down to find out when and how the catheter would deform or kink. We did this by measuring the volume and the area that “opens” when the catheter bends or is compressed.