New invention to help the wind industry recycle fiberglass

Press release

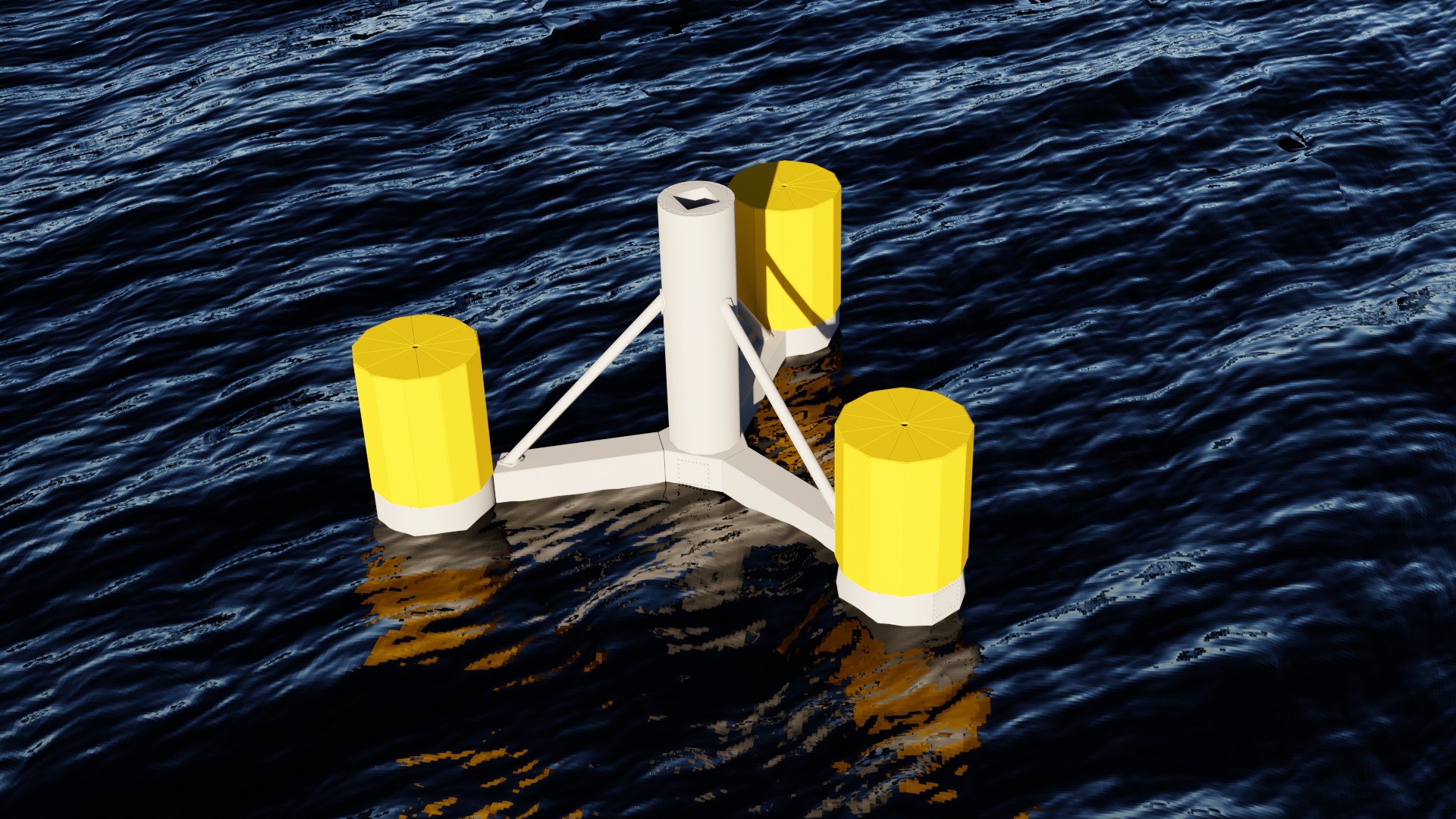

The engineering company FRECON A/S has taken out a patent for a new invention: A floating foundation for offshore wind turbines with pontoons made of recycled fiberglass. The patent has potential to contribute to making the wind industry a more circular economy by recycling end-of-life turbine blades.

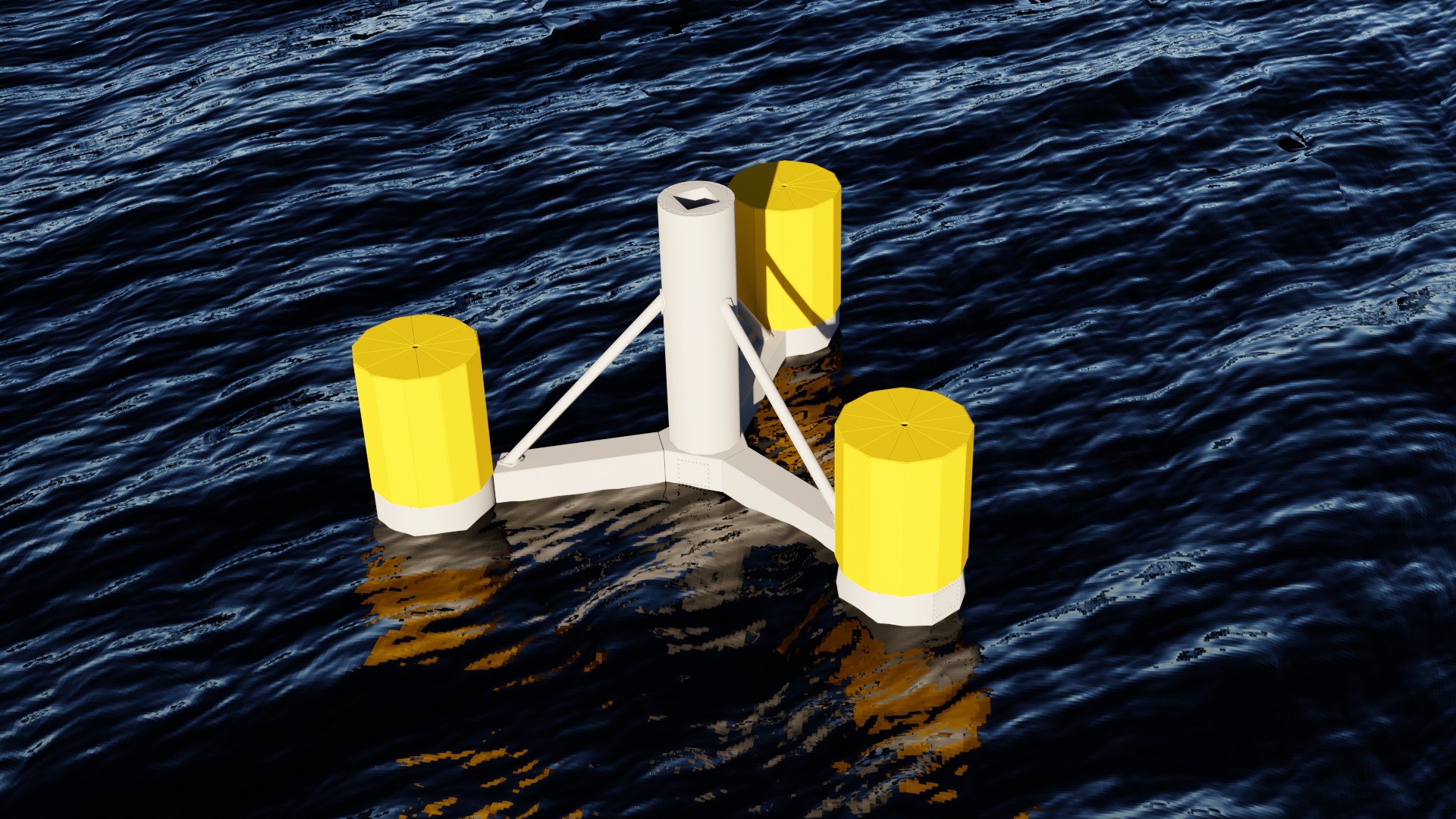

The floating foundation floats by means of pontoons made of recycled fiberglass and is designed for large offshore wind turbines. The floating foundation is intended for sea depths of 60 meters and more, where, for example, monopile foundations cannot be used. This enables countries with great ocean depths the opportunity to harvest wind energy alongside other countries. At the same time, the foundation is relatively gentle on the seabed, as no piling is required. Furthermore, a concrete foundation is simply cast for anchoring on the seabed. The concept is scalable and created for turbines of 15+ MW.

The patent has already been granted in Denmark and has received positive feedback on the application for an international patent as well. Here the invention is rated high on the parameters “Inventive Steps” and “Industrial Applicability”.

Photo: Floating Foundation

“We are very excited and proud of our innovate mindset and skills. The floating foundation is no exception, and as we see it, the pontoons of recycled fiberglass have great potential to contribute to recycling worn out turbine blades, rather than simply sending them to landfill. We now hope to find a business partner with whom we can further develop the patent, someone who is as enthusiastic about it as we are.”

says Ida Rasmussen, CEO of FRECON A/S.

The construction, which consists of a frame of pretensioned concrete and three pontoons of recycled fiberglass, ensures correct buoyancy for the floating foundation. The modular design has been created so that the foundation can be cast and assembled locally, which reduces the need for transportation as well as give work to local workers.

The idea of a floating foundation with pontoons made of recycled fiberglass arose as a growing frustration over the fate of end-of-life wind turbine blades as e.g., buried or burned. Frederik Rytter, co-founder, and owner of FRECON A/S, thought that there had to be a way to recycle the strong fiberglass material while retaining as much of its strength as possible. At the same time, he was brewing on an idea of a new concept for floating foundations that would allow more countries to harvest wind energy.

“The idea of recycling fiberglass from wind turbine blades arose because of the pontoons in the floating foundation. I wanted to create them in a light material. Therefore, the idea arose that they could be made of recycled fiberglass granulate, if the material could be sorted and recast correctly.”

explains Frederik Rytter and continues,“The lack of recycling options for fiberglass has been a challenge for many years. Fiberglass is a good and strong material that can withstand a lot of stress and does not break easily. We therefore began to investigate how we could recycle the material, because as turbine blades are replaced, the challenge of handling the end-of-life blades grows.”

Photo: pontoons

Fiberglass has many properties that make it an attractive material to recast. Its strength in particular has been thoroughly tested offshore – both in the wind and ship industry. With a floating foundation consisting of e.g., recycled fiberglass, there is potential to extend the lifetime of the existing materials by 25-30 years, explains Frederik Rytter.

At FRECON, they have already experimented with small prototype tests for the manufacturing method of recycling fiberglass and have seen good results. Now they look forward to working on the patent for the floating foundation and unfolding its full potential.