Nacelle cover – maturation from basic design to functional and producible design

For 20 years FRECON has worked with mechanical design, construction, and calculation in several industries. Within the wind industry, we have, among others, worked up a strong position in the market for construction of nacelle covers, and a cooperation with Envision Energy – one of the world’s leading wind turbine manufacturers.

In FRECON, we have strong competencies within composite constructions and have provided support on a two-digit number of nacelle cover solutions to several of the largest wind turbine manufacturers. Our competencies in this area are in high demand.

Senior Solution Specialist and Partner, FRECON, Frederik Rytter, explains:

”Through the years, we have followed developments at the same time as we have gathered ‘best practice’. This is of great value to our customers. Moreover, it is of great value that we understand how to combine our knowledge for the benefit of the individual customer. In each customer project, our experience and specific competencies are increased, which becomes advantageous in our next customer projects – although all nacelle covers, of course, have different specifications and our cooperation with customers is based on an NDA.”

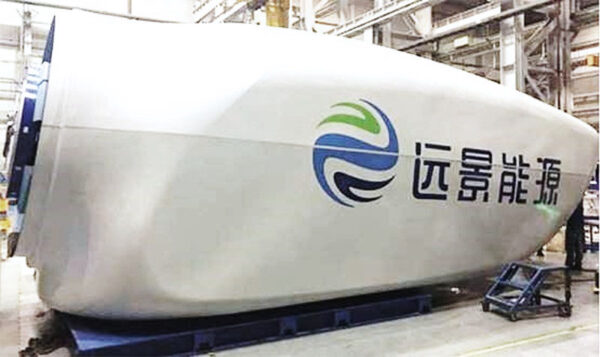

In cooperation with Envision Energy, the project was to transform a basic design of a nacelle cover into a producible and functional nacelle cover with the correct strength to survive a ”50-year storm” and with a strong attention towards total cost of ownership and specific customer requirements.

Envision Energy came up with an exciting, innovative, challenging, and aesthetic basic design that consisted of an eggshell form in solitary 3D surface. To mature this eggshell into a final nacelle cover, FRECON parameterized it.

Such a complex 3D surface required the right qualified competencies, thus in FRECON we could benefit from our many years of experience in considerations of multiple and simultaneously parameters such as design requirements, functions, structural integrity, production, and cost price.

Also, by using FRECON’s methodological approach to construction work and our unique and effective integration between design and calculation software, we could implement particularly many and fast iterations on optimizing of physical design and on the product’s structural properties. Hence, in this nacelle cover project, this method allowed us to utilize the double curved surfaces to quickly and efficiently give the nacelle cover more strength while at the same time reducing the material thickness.

Photo: Envision Energy’s nacelle cover for ’Onshore Smart Wind Turbine 2.X MW’ (Photo kindly loaned by Envision Energy)

Rasmus Gottlieb Jakobsen, Lead Design Engineer, FRECON:

“In the cooperation with Envision Energy, we transformed the basic design from a predominantly sandwich construction into a single skin with a minimal consumption of foam and with built-in beams in the particularly exposed places. These strategically placed reinforcements were to ensure that the nacelle cover could withstand e.g. the snow and wind loads it is exposed to. Moreover, this type of construction also made it possible to construct the nacelle cover in a thin layer of fiber without losing the strength of the construction. This was a great cause of why we so rapidly could succeed in reducing 4.8 mm to 4.0 mm glass fiber and remove large parts of the foam reinforcement.”

In addition, FRECON got great opportunities to think innovative to cost optimize and innovate features for the nacelle cover. For example, this allowed the cooling intake to the gearbox to be directly integrated into the nacelle cover, which reduced the final number of molded parts.

Peter Laugesen, Lead Design Engineer, FRECON:

“We managed to construct a nacelle cover with suitable draft angels and thus with an efficient moulding ejection. This gave Envision Energy a quick and smooth moulding, and a subsequent very simple assembly.”

Today, the nacelle cover can be seen on Envision Energy’s beautiful and innovative ‘Onshore Smart Wind Turbine 2.X MW’, which is known for providing maximum performance, optimizing energy yield, and minimizing downtime.

Turbine Chief Engineer, Envision Energy