FRECON is sparring partner in the design of a larger food processing line

As an experienced engineering house within mechanical design for the food industry, FRECON has contributed during the further development of a larger washing plant for DANA-Technology.

DANA-Technology is an expert in the development of production equipment and machinery for the food and pet food industry. As a technologically innovative company, they create efficient and long-lasting production lines.

In 2020, FRECON’s task was to contribute as a sparring partner during the design of a larger washing plant for strawberries, which will be part of a food processing line.

“The order for the strawberry project was signed in January, before we knew what effect Covid-19 was going to have for the entire industry. However, at DANA-Technology we were aware that with such a large project and with a set delivery time, we had to seek professional design help from outside,” says Vagn Hansen, CEO at DANA-Technology and continues:

“We chose FRECON, as they offer consultants with experience in the design of machinery and equipment for the food industry. In a positive collaboration with our own engineering staff, FRECON’s consultants have solved the task within the set time frame and economy agreed with our partners.”

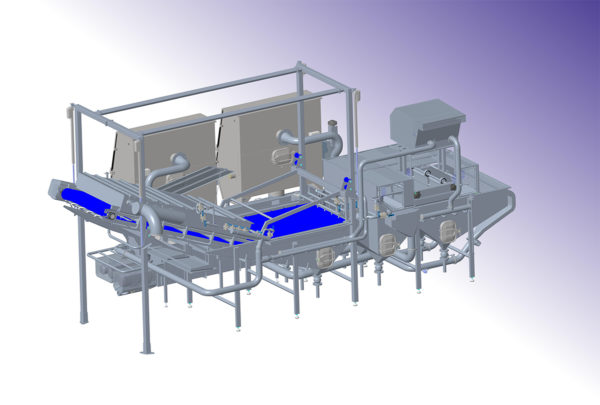

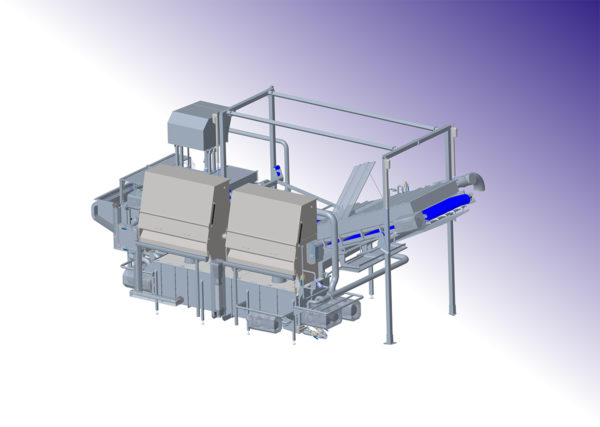

Compact solution with many different functions

The solution consists of a steam-heated pump vessel with two mechanical parabolic filters. Using flow vessels, strawberries or potatoes are mechanically cleansed and then passed through various nozzle pipes. Finally, they are lifted via a conveyor belt through a tunnel and dried with so-called air knives before they are ready for freezing.

High production efficiency is ensured, as the plant is be able to handle 10 tons of strawberries per hour or a correspondingly large amount of potatoes. Together with the existing plant, it brings the capacity up to 20 tons of strawberries per hour. In addition, the conveyor belt can be dismantled and lifted when the system is to be cleaned.

FRECON solved challenges in the design phase

As an expert in mechanical design and with extensive experience in solutions for the food industry, FRECON acted as a sparring partner during the design process. Sonny Dam, Senior Design Engineer, solved challenges along the way:

“DANA-Technology came up with an incredibly interesting task, which was very much about ensuring a smooth design phase. The challenge was that the machine was compact from the beginning, which means that the many and new functions must play together in a relatively little amount of space. At the same time, we had to ensure that the plant continued to comply with various requirements for food production,” explains Sonny Dam and continues:

“Not least, it was about delivering a product that is easy to understand and use at the company that is ultimately responsible for the physical manufacture of the plant.”

Dansk Stålmontage is the manufacturing company of the washing plant and partner of DANA-Technology. DANA-Technology that have previously worked with FRECON is pleased with the collaboration:

“As a project manager in other contexts, I have previously worked with Sonny, and was in no doubt that he was the right man for the job,” says Lars Skovbjerg Knudsen, Senior Project Manager at DANA-Technology. “As always, he fully met my expectations of solid design work and sparring when needed.”