FRECON brings extensive experience with mechanical design for the food industry in new dairy project

In a project with Vase-Tec and HSV Combi, FRECON helped optimize and calculate a rack filler and transport solution for a major Nordic dairy company.

A new task from a major customer within the Nordic dairy industry meant that the two companies Vase-Tec and HSV Combi was in need of extra engineering powers. With strong competencies in mechanical design for the food industry, it resulted in a valuable, collaborative project with FRECON’s experienced engineers.

The customers HSV Combi and Vase-Tec are two companies with the same starting point. Knud Erik Vase is the man behind the company Vase-Tec, which for many years has designed and calculated dairy equipment, and HSV Combi is a development of this. Mads Saetterup is Knud Erik Vase’s grandnephew and as a skilled craftsman, he has learned the know-how and network that are now used in HSV Combi together with Anders Henriksen.

Optimization and calculation of dairy equipment

While Knud Erik Vase had already given the solution for the Nordic dairy company some thought, FRECON was given the task to optimize and calculate the design using the customer’s 3D modeling software, Alibre. On the collaborative assignment with Vase-Tec and HSV Combi were Senior Design Engineer Thomas Christensen and Lead Design Engineer Peter Jacobi, who says:

“Knud Erik had made a number of sketches for the design of the solution, which we continued to work on based on the guidelines given. In that process, we came up with several optimization proposals and made a number of strength calculations. We also recommended an alternative motor, which could ultimately provide a lot of savings.”

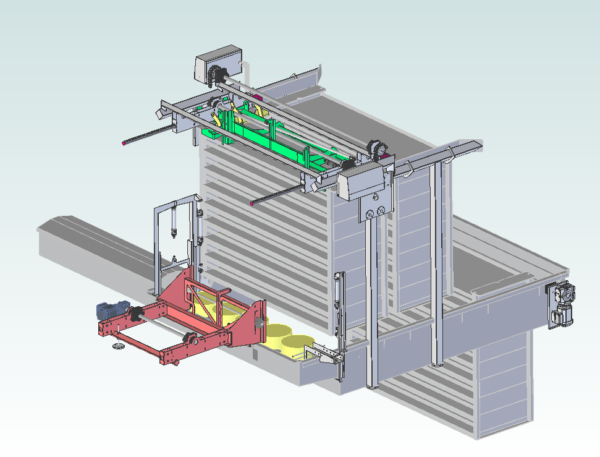

Rack filler for 1.5 tons of cheese

The finished construction for the dairy customer had to meet several criteria. On one hand, the machine must be able to carry up to 1.5 tons of cheese, be able to transport the cheeses three meters above the ground and place them in a large vessel with brine, which is to make the cheeses delicious and soft and ready for transportation. Not least, the construction must comply with certain requirements for food production.

“Throughout the entire design process, we have benefited greatly from both Knud Erik’s extensive knowledge from the dairy industry and our own experience with design for other segments in the food industry,” says Peter Jacobi. “Hygiene and the ability to keep the construction clean is crucial. It is everything in this business.”

Valuable collaboration with new professional insights

If you ask Knud Erik Vase about the project with FRECON, there is only positive feedback. The collaborative assignment offered mutual professional sparring, and he has thus become more open to using external help in the future.

“Peter and Thomas offered just the right competencies we were looking for. They quickly got acquainted with both the 3D software we use and the whole mindset behind the project. With their help, we have completed the constructions about 97%. After that, I did the last bits myself. From the beginning, I was a bit skeptical about the use of external help in general and a possible lack of focus. But the experience has only been positive. Peter and Thomas have fully lived up to what we had hoped for,” Knud Erik Vase finishes.