Valuable collaboration on optimizing and designing storage solution and transport of cheeses

FRECON’s experience with design of machines and handling equipment was exactly what Vase-Tec and HSV Combi was looking for when optimizing and designing a rack filler and transport solution for a major Nordic dairy company.

HSV Combi and Knud Erik Vase from Vase-Tec have many years of experience in the design and calculation of dairy equipment. On their latest project for a major Nordic dairy customer, Vase-Tec and HSV Combi sought for help and FRECON was chosen based on their competencies within mechanical design of food processing equipment.

HSV Combi is built on the know-how of Vase-Tec

HSV Combi has the two skilled craftsmen, Anders Henriksen and Mads Saatterup, as owners. Mads Saatterup acquired his design, calculating and drawing skills at his grand uncle’s company, Vase-Tec. As grand uncle Knud Erik Vase wants to retire, HSV Combi´s extensive know-how and network now build on the efforts that Knud Erik Vase acquired through the years.

Optimization and calculation of design

Thus, it was Knud Erik Vase who worked alongside Thomas Christensen and Peter Jacobi from FRECON. The two FRECON engineers began by familiarizing themselves with the 3D modeling software Alibre, which is the design tool used by Vase-Tec.

“Knud Erik had made a number of sketches for the design of the solution, which we continued to work on based on the guidelines given. In that process, we came up with several optimization proposals and made a number of strength calculations,” says Peter Jacobi. “We also recommended an alternative motor, which could ultimately provide a lot of savings.”

Hygienic rack filler for cheeses

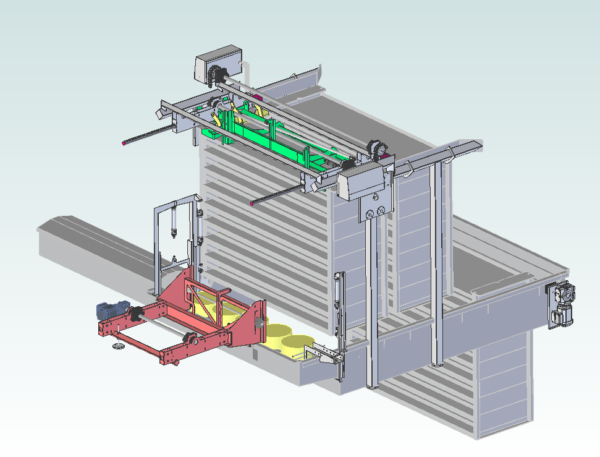

The construction, a rack filler, must be able to carry 1.5 tons of cheese, which is to be transported three meters above the ground, placed on shelves and then moved to a large pool with brine, where the cheese becomes deliciously soft, before transportation.

“Throughout the entire design process, we have benefited greatly from both Knud Erik’s extensive knowledge from the dairy industry and our own experience with design for other segments in the food industry. Hygiene and the ability to keep the construction clean is crucial. It is everything in this business,” says Peter.

Great commitment and high professionalism

Knud Erik Vase looks back with satisfaction on the project, where he experienced great commitment and a high level of professionalism from FRECON’s engineering team.